Without any knowledge about the machine setting, achieving a good print demands a miracle. Would you need a print without miracle aid, read the following post.

One of the most important instruments for adjusting and controlling a printing machine which is a MUST for any printing house is Dial Indicator which is used for checking different parts of machine involving in printing. Each time the mandrels are changed in tube or cup printer and etc. they must be checked by the dial indicator which is available everywhere with reasonable price.

While using the device, try not to fasten it too tight to the magnetic stand; it may result in serious damage to it. Dial indicator is a measurement instrument which measures precise unit as 0/01mm. How thick is 0/01mm you ask? Well, compare it with a single human hair of human which is about 0/05mm. So it can measure things as thin as one-fifth of a hair.

In cup printers, it is used for the recognition of:

- Differences between mandrels as they to be exactly the same.

- Deflection of the mandrels

- Deflections of indexing axis

- Deflections of plate cylinder

- Deflections of drum

Testing point 1 and 2 is necessary every time you replace the mandrels. The rest should be tested at least every two months.

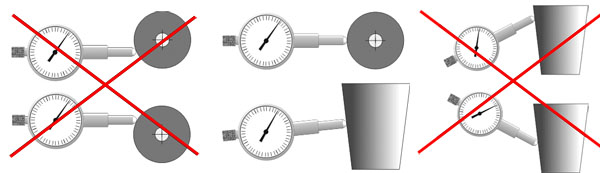

How to use a dial indicator

The magnetic stand of the dial indicator has strong magnet which sticks to ta fixed part of a machine in order to check the axes by spending some short minutes for working with the device will let you handle and master the base. The most important point in using the indicator is it needs to be perpendicular to the axes.

When to use dial indicator when encountering problem with a cup printer

- One of the 8 cups on the indexer is not printed or has a print ghost

- Some parts of the cup has not been printed or has a print ghost

Solutions:

In the above cases, you must use the dial indicator. However, unfortunately, in the workshops in the workshops with poor technical knowledge, the problem is solved by increasing the pressure of drum which damages the cylinder.

Gently, turn the mandrel by your hand one complete round. The desirable result is no more than 0/05mm. The lower the number is the better. If the deflection is more than 0/05mm, some parts will remain unprinted. Apply the above test for the rest of the mandrels.