To have a beautiful print, hiring a professional graphic designer is a MUST to start the design. A print without a valuable design leads to spoiling of others’ efforts. A central feature of dry offset printers is using CMYK colors. A good graphic designer, who knows such machines well, will be capable of delivering good artwork.

The main difference is that these machines have ink-mixture limitation. In order for printing green color in offset paper printers, blue and yellow dots are printed beside each other and you see them in green. By putting the four small colored dots, CYAN, MAGENTA, YELLOW, and KEY (black), beside each other all the colors are printed on the artwork. You can see the dots easily by a magnifier. However, in offset printers, the graphic designer should consider the number of machine’s colors to design accordingly. For example, if your machine is a five color printer, your artwork needs to contain at most five colors, which each ink unit needs to print each color separately.

What is the problem of color combination?

In these machines, the inks are transferred respectively on a medium rubber, and then printed on the object. But if the colors overlap, you will experience ink contamination. If a part of a black and yellow color overlap, the yellow print will be contaminated with black. That’s why you will never be able print green by overlapping yellow and blue. This problem does not occur in paper cup printers because the colors are not transferred simultaneously but respectively; so transferring color from a plate to another is impossible.

Techniques of making color combination in dry offset machines

The points that an operator needs to consider about color combination is that darker colors should be used in the last ink units. Additionally, price ink adjustments should be done to result in the least overlap. These are the only techniques that the operator should use; the rest depends on the art of graphic designer.

First Technique: Less yellow use

A general point that a graphic designer needs to know about is using as less yellow color as possible in the parts that has color combination as yellow is the most vulnerable color in color contamination comparing to the other ones.

Second Technique: Using pure yellow

If you have to use yellow trams on the other colors, try to use yellow alone in other parts as much as possible.

Suppose that yellow ink unit has two ink input and one ink output. It means that while the ink unit takes ink from the ink fountain, the plate is also colored because of its contact with the ink from blanket and blanket then transfers the ink to the form rollers as well. Now if we try to increase the amount of input pure yellow ink to be more than other unwanted inks transferred from blanket to form roller, there would be less contamination.

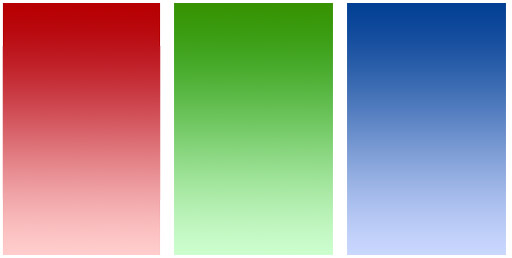

Third technique: Overlapping of similar colors with no problem

You can use two dark and light green colors as your background so that the colors overlap each other as trams when reaching from both sides; it will make gradient overlay background from dark green to light green. This technique is the same in similar colors. Because of the similarity of the colors the effect of color contamination reaches to the minimum and can be ignored.

Fourth Technique: Black dots on other colors

Contrary to yellow, black is barely contaminated. So, you can systematically add black dots on other color patterns to make beautiful images. I have seen a fantastic photo of a strawberry made of red and black color.

However, you should try using lesser black than red in this method as well. Why? Operator fills the first ink unit with red and the last one with black. It means that the blanket takes the red ink first and then contacts black. If the black ink on the plate contacts with the red color on the rubber blanket, black will be less affected because of its higher saturation. But you need to be cautious about yellow, because the blanket, contacting the printing piece, does not transfer whole the ink and then in next turn it will be blackish and if contacts with yellow, will contaminate it.

Using the above techniques, a graphic designer and machine operator will be able to make beautiful print on your products.