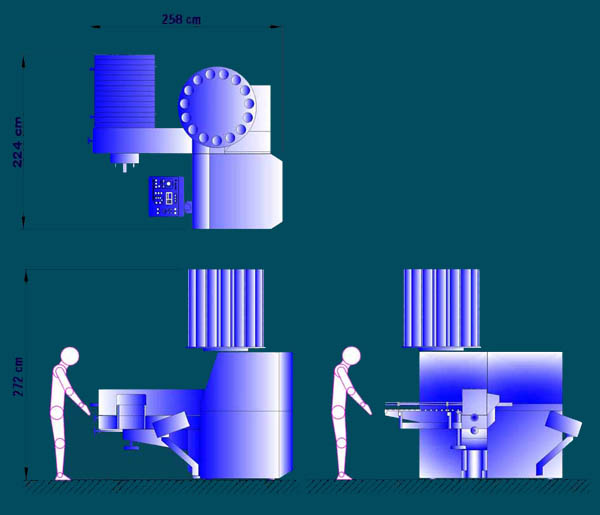

More Details on Five Color Cup Printer

Model: N-DO-6

SPECIAL SPECIFICATION

FEEDING SYSTEM

- The capacity of input cup bank, 15,000 cups, is almost higher than all the print machines with input cup bank among the cup printing machines. Working space has reached to its minimum extent as a result of the method of design. All the cells start to be filled out from the bottom easily and after finishing one row of cups the other row is replaced automatically. The automatic replacement enables the operator to do other jobs such as gathering the cups, bringing or taking the cartons, etc after filling out the cup bank.

- In case the operator forgets feeding, while the cup bank checks out the rows for the cups one by one, it decreases the speed of the machine to the minimum rate and informs operator with the signal and light alarm. Finally, if the cup feeding becomes O.K, the speed of the machine goes up to the adjusted rate, otherwise the machine stops.

- Feeding, ejecting and positioning of the cups in the cup bank are in a way that the shortest cups can be transferred to the feeder completely without any problem.

PRINT UNIT

- The self adjustable double gear, transfers the motion from the central gear to the cylinder plate. So that looseness of the gears lessens down to the zero point in any situation in order to guarantee printing without any slide or shadow especially in high printing speed.

- Two rollers with independent and scaled setting transfer the ink on the plate simultaneously.

-

Two big oscillator rollers have been set in every station to make the print shade minimum

with a reliable mechanism.

To take out the ink tank from the print station just you push a springy clamp.

-

This cup printing machine is equipped with the most accurate mechanism for adjusting ink

consumption amount with scales on printing stations.

Untightening of only three screws accessible right in front of the whole system of each print station, can separate the related attachments completely. (Except the plate cylinder system)

INDEXING UNIT

- Two vacuum pumps work to take and hold the cups; one transfers the cups from the feeder onto mandrel fast and the other fastens the cups tightly to the mandrel with a strong vacuum while the machine is printing.

- In the design of N-DO-6, mandrel rotating rolling is fixed inside Index and not replaced with mandrel; so mandrel is machined aluminum piece that joins to relative bushes with a single screw.

- Very fast replacement of mandrel

- Completely secure installation

- Very low expenses of making mandrel

Advantages of this design are:

UV DRYING SYSTEM

- The UV dryer system includes three lamps which can be turned on proportionally to the container dimension.

- Three analogue input in PLC with three sensors show lamps' charge status on the panel to operator and turn on the air vent system automatically.

- By pushing aside the two springy clips, UV lamps will be accessible for operator to change or remove any problem.

- The dryer system includes two air vents that one blows the cool, filtered and clean air onto the lamps and the other sucks out the warm air and ozone gas created by UV lamps.

- The situation of UV dryer system does not let the operator to be exposed under direct radiation of UV even when the cover is open.

EJECTION SYSTEM

- Having been printed and dried, the cups are re-stacked full automatically in the preset numbers on the output table.

- In N-DO-6, also a reliable and fast re-stacker system has been set to deal with the short cups exactly.

- Two holding nails from two sides of cup with sinuous and synchronized moves with indexing separate the cups from the mandrel and put them inside each other.

- Also two holding nails from two sides of cup with a preset counting command separate the columns of the cups. Besides, when the cups are short, a holder equipped with a DC electromotor, moves after cups to prevent them from falling.

STRUCTURE AND SHAPE

- Certainly, N-DO-6 has most perfect cover among other cup printing machines. Except cup bank there is no moveable part out of the cover; so working with this machine is much safer. Because of the limitation of machine size, it is easy to keep the machine cool; moreover, the whole machine, especially dozens of rollers and soaked blanket of ink, can be kept away from the dust outside.

- The cover has five hinged doors opening out to let the operator accesses the different parts of the machine i.e. feeder, re-stacker system, mandrels, etc. Vacuum pumps are also accessible through an out-opening door in cover. Besides, the whole printing-part cover rises by pneumatic jacks so that operator can access all the print parts. Rest of the cover parts have been made accompanying two accessible springy clips fastened to the body.

- All the parts are inside a package and have been installed on an adjustable frame. Parts like electronic panel, pump, wire, pipe, hose, etc. do not rest on the ground. Air and electric input is possible through a leading pipe entered from the top into the machine.

PLC

- PLC and its monitor have been programmed in a way to be able to report more than 60

faults and in each case guide the operator with various pages including the related

points such as:

The functioning of each fuse, any problem in input electrical power, an air pressure drop, most of the likely problems in the function of pneumatic equipment and related sensors, etc.

- If any of the three input electrical wires breaks off for instance, PLC stops the machine, and the monitor reports the error; even the input terminal number is reported to the operator. If necessary, several pages for troubleshooting will be presented.

- The neutral wire in the electrical system of the machine has been removed by using an isolator transformer. (There is no need for the neutral wire in this machine). More than 650 pages have been designed for PLC's monitor to be used in different situations.

- Checking out the machine, troubleshooting and software-upgrading is possible by hooking up to the telephone lines every where.

- The most important feature of PLC's software is that everyone with a single password can operate and manage all the parts and panels like settings, options, mending, changing number for preset counters and modifying the password, etc. without any former instructions.

GUARANTEE

The machine benefits from one year full guarantee and at least 10 years after sales services.